The main reasons for LED dead lights are as follows:

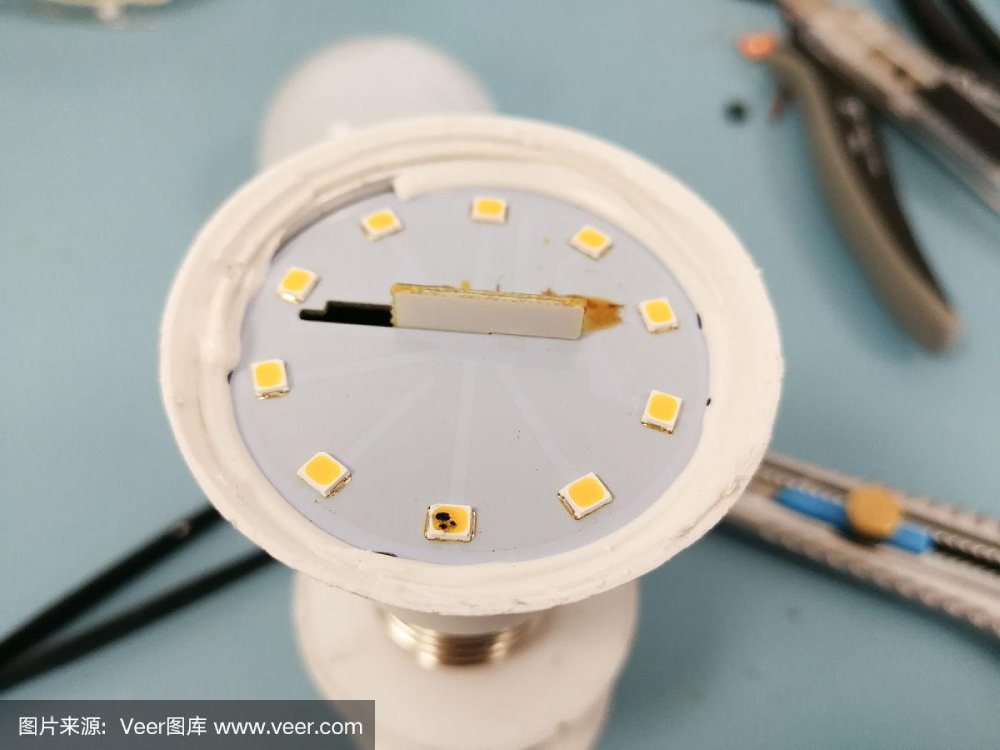

1) Excessive LED leakage current causes PN junction failure, making the LED light off

2) The internal connection leads of the LED light are disconnected, causing no current to pass through the LED and causing the light to die

How to prevent LED dead lights?

We know that human body static electricity (ESD) can reach about 3000 volts, which is enough to break down and damage LED chips. In the LED packaging production line, the grounding resistance of various equipment must meet the requirements. Generally, the grounding resistance is required to be 4 ohms. In some high-requirement occasions, the grounding resistance must even reach ≤2 ohms.

Human body static electricity is also very harmful to LEDs. When working, you should wear anti-static clothing and anti-static rings, and the anti-static rings should be well grounded. There are anti-static rings that do not need to be grounded, and the anti-static effect is poor. It is recommended not to use such products. If the staff violates the operating procedures, they should receive corresponding warning education, which also serves as a reminder to others.

The amount of static electricity on the human body is related to the fabric of the clothes people wear and their physical constitution. When people take off their clothes at night in autumn and winter, it is easy to see the discharge phenomenon between clothes. The voltage of this static discharge is 3000 volts.

Some companies use manual welding with a 40-watt ordinary soldering iron. The welding temperature cannot be controlled. The soldering iron temperature is above 300-400℃. Excessive welding temperature will also cause dead lights. The expansion coefficient of LED leads at high temperatures is several times higher than that of about 150℃. The internal gold wire solder joints will be pulled apart due to excessive thermal expansion and contraction, causing dead lights.

In addition, when silicone-encapsulated LED chips are reflowed, the colloid will rupture and the gold wire will be broken due to moisture expansion and contraction, which will also cause LED dead lights, or the lamp body will light up when pressed and go out when released. In this case, the LED needs to be baked and dehumidified before SMT reflow soldering.